TEST AREA

Test area

Our products have always been manufactured in order to reach the hightest standards in quality and safety because we want to be sure that our systems are up to their function.

To verify compliance with the specific functional and performance requirements, we carry in our test area a set of tests, measurements, investigations and inspections. Our products are qualitatively tested before, during and after production by qualified experts. Even more for 15 years we relied upon several certification authorities to certify our products, submitting them to several tests apt to determine in an objective way their performance.

The design and production quality of IAM Design item allowed us to obtain certifications according to the standards currently in force in many european countries and to ensure the choice of our customers.

In its factory, IAM Design created a tests area, where all output is throughly tested. You can see below someof the tests we regularly perform.

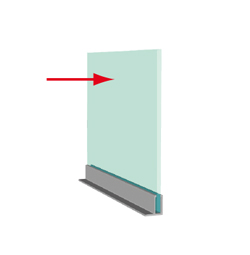

HORIZONTAL PRESSURE RESISTANCE

This test is achieved as recommended in the regulation (UNI eN 1991-1-2, UNI 10806:1999, D.M. 14/01/08); it examines mechanical resistance to loads in railings, balustrades and balconies. Horizontal thrusts are applied up to the handrail for a fixed time; in this way, item break load can be identified.

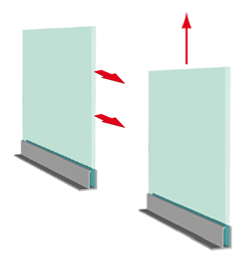

TRACTION RESISTANCE

This test is achieved as recommended in the following regulations: UNI 10808:1999 tests mechanical resistance to loads in railings, balustrades and balconiy panels. UNI 10809:1999 establishes size features and mechanical performances of ready-made railings, balustrades and balconies, depending on the final use and installation location.

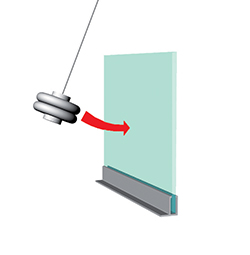

IMPACT RESISTANCE

This test is achieved as recommended in the regulations. We make a shifting body crash into the most critical spot of a glass sustained by Glass U profiles; from the release to the crash, the 1,5 m long and 50 kg heavy pendulum goes through 30 degrees. UNI EN 12600:2004 identifies a procedure for the pendulum crash test. UNI 1087:1999 examines mechanical resistance to loads in railings, balustrades and balconies.

CORROSION RESISTANCE

This test is achieved as recommended in the regulation UNI EN ISO 9227:2012 , that identifies device, reagents and procedure to follow in case of neuter salt mist (NSS), acetic-salt mist (AASS) and cupro acetic salt mist (CASS) tests. It therefore evaluates corrosion resistance to metallic materials, with or without anticorrosive protection, permanent or temporary. Items are placed in a room that nukes a 5% NaC1 saline solution, with pH between 6,5 and 7,2 and a +35°C fixed temperature. Test duration: 120 hours.

Italiano

Italiano